Sodiceram stands out as a highly versatile and increasingly popular material, blending science and practicality for a wide range of modern applications. Whether you are an engineer, architect, or simply a curious learner, understanding it is crucial in today’s world. Known for its robust properties, sodiceram has quietly revolutionized industries from construction to medicine. But what exactly is it ? At its core, sodiceram is a specialized ceramic compound designed to deliver superior performance under challenging conditions. It is often chosen for its unique blend of strength, thermal resistance, and electrical insulation abilities. As we dive into the world of it , you’ll discover how this material is shaping the future of technology and infrastructure.

Understanding the Chemistry of Sodiceram

Delving deeper into the makeup of sodiceram, we find a blend of various chemical elements that contribute to its remarkable qualities. Typically, it comprises silicates, alumina, and specific additives that enhance its physical characteristics. Its molecular structure is engineered to deliver maximum strength and durability, even in extreme environments. The chemistry behind it not only makes it stable under high temperatures but also gives it resistance against corrosion and chemical attacks. This composition results in a ceramic that is tough, reliable, and adaptable for several demanding roles. The science is intricate, yet the results are straightforward—sodiceram consistently delivers where traditional materials may falter.

History and Evolution of Sodiceram

The journey of sodiceram began decades ago, rooted in early ceramic science experiments that aimed to create more resilient materials. Researchers, driven by the need for robust industrial ceramics, developed it as a response to the limitations of traditional pottery and porcelain. Over the years, sodiceram has evolved with innovations in material science, becoming a staple in high-tech sectors and everyday construction. Today, it’s not uncommon to find sodiceram-based products in places ranging from luxury homes to cutting-edge laboratories. Its evolution speaks volumes about its adaptability and the persistent human quest for better, stronger, and more reliable materials.

Why Choose Sodiceram Over Other Materials?

When evaluating materials for a project, it often rises to the top of the list for several compelling reasons. First, its unmatched durability and resistance to wear make it ideal for both high-traffic environments and sensitive applications. Unlike metals, it does not corrode, and it maintains its structural integrity under stress. In comparison to plastics, it remains stable under extreme temperatures, making it suitable for challenging industrial processes. Choosing it means investing in a material that is both versatile and reliable, reducing long-term maintenance costs and providing peace of mind.

Key Properties of Sodiceram

The unique properties of sodiceram are what truly set it apart. It boasts impressive compressive strength, meaning it can withstand heavy loads without cracking or deforming. Its low porosity makes it resistant to moisture absorption, a vital feature for use in humid or wet environments. Furthermore, it exhibits excellent chemical inertness, ensuring it doesn’t react with most substances it contacts. These combined properties allow sodiceram to serve reliably in everything from architectural projects to medical devices.

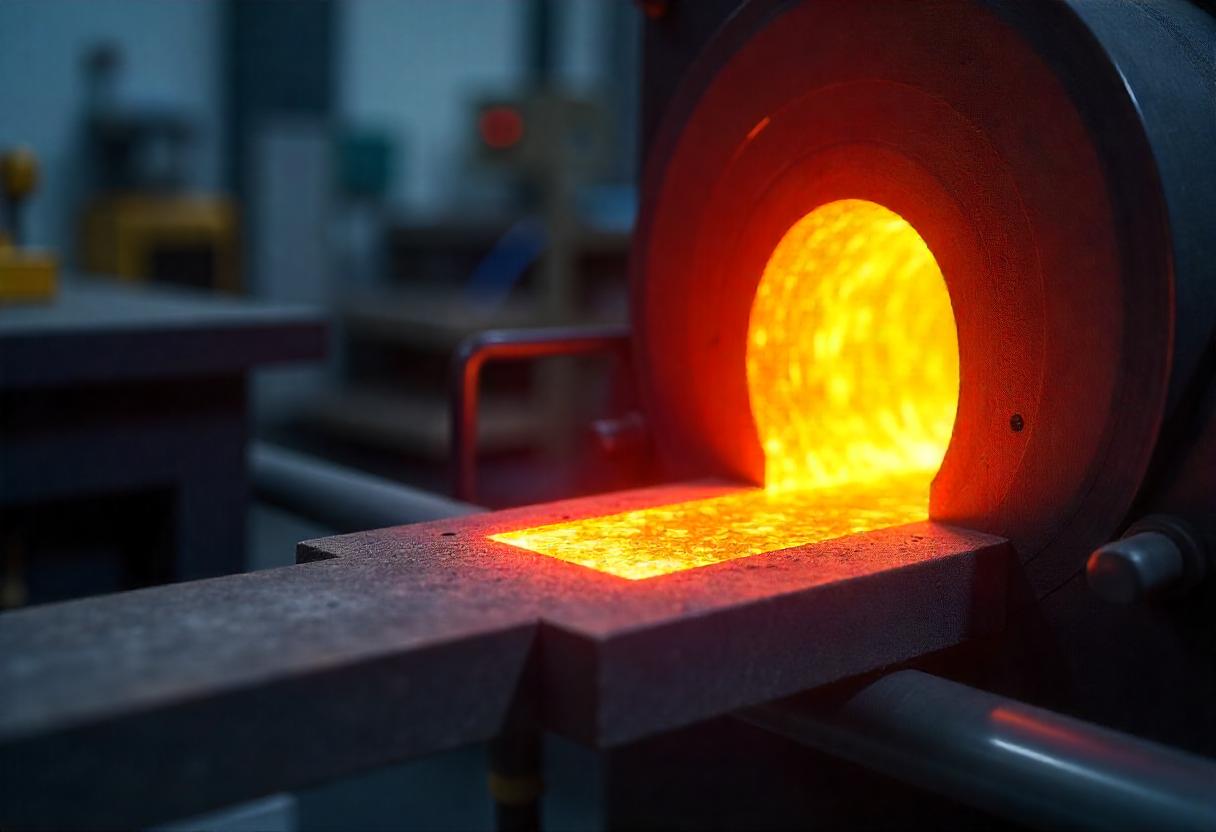

Thermal Resistance of Sodiceram

Heat resistance is one of sodiceram’s standout features. This ceramic can endure high temperatures without breaking down or losing strength. For industries that operate furnaces, kilns, or other high-heat environments, it is a material of choice. Its stability under rapid temperature changes also prevents the risk of thermal shock, a common problem with other materials. This makes it ideal for components that experience fluctuating thermal conditions, ensuring safety and longevity.

Electrical Insulation Abilities

Sodiceram’s non-conductive nature is a significant advantage in electrical and electronic applications. It serves as a perfect insulator, safeguarding sensitive equipment from electrical surges and preventing short circuits. In fact, the dielectric properties of it make it indispensable in circuit boards, transformers, and high-voltage systems. Engineers value sodiceram for its ability to maintain performance and safety in electrically demanding settings.

Applications of Sodiceram in Construction

In the construction industry, sodiceram is valued for its robustness and aesthetic appeal. It is frequently used in floor tiles, wall panels, and façade elements that require both style and substance. The material’s resistance to scratches, stains, and moisture allows it to retain its beauty and structural integrity for decades. Furthermore, it ’s adaptability means it can be crafted into various shapes and finishes, making it a favorite among architects and designers aiming to balance function and form.

Sodiceram in Advanced Manufacturing

Manufacturing processes demand materials that can handle rigorous use and maintain consistent performance. It fits this need perfectly. From machine parts to specialized tools, sodiceram’s resilience to abrasion and high temperatures supports long-term use and efficiency. It has become a staple in advanced manufacturing settings, supporting both mass production and bespoke, high-precision tasks.

Role in Aerospace and Defense

The aerospace and defense sectors are known for their stringent material requirements.It finds its place here as a lightweight, strong, and heat-resistant material ideal for engine components, protective shields, and structural parts. Its ability to withstand extreme pressures and rapid temperature changes makes it invaluable for spacecraft, aircraft, and defense applications where failure is not an option.

Medical Uses of Sodiceram

In healthcare, biocompatibility and cleanliness are paramount. Sodiceram’s non-reactive and sterilizable nature makes it a go-to choice for surgical instruments, dental implants, and prosthetics. It resists bacterial growth and can be easily cleaned, reducing the risk of infection. With continuous research, new medical applications for sodiceram continue to emerge, promising safer and more effective treatments.

Environmental Benefits and Sustainability

Sodiceram is not just durable—it’s environmentally friendly as well. Its long lifespan reduces waste, while its inert composition prevents the leaching of harmful chemicals into the environment. Many sodiceram products can be recycled at the end of their lifecycle, supporting a circular economy. Using it also means fewer replacements, saving both natural resources and money in the long run.

Cost-Effectiveness and Longevity

Although the initial investment in it might be higher compared to some alternatives, its durability and low maintenance costs deliver excellent value over time. The material’s resistance to wear and tear means fewer repairs and replacements. This long-term reliability translates into significant cost savings, especially in demanding industrial or commercial applications.

Challenges and Limitations of Sodiceram

No material is without its limitations. Sodiceram, for all its strengths, can be brittle under certain types of impact or stress. It also requires specialized manufacturing techniques, which can increase costs and production time. Additionally, while it excels in many areas, it may not be suitable for applications requiring significant flexibility or elasticity.

Future Trends in Sodiceram Research

The future of it looks bright, with ongoing research focused on enhancing its properties and expanding its uses. Innovations in nanotechnology and 3D printing are opening up new possibilities for customized sodiceram components. Scientists are also exploring ways to make production more energy-efficient and sustainable, paving the way for even broader adoption in coming years.

Case Study: Sodiceram in Real-World Projects

Several high-profile projects showcase sodiceram’s capabilities. For example, in a major metropolitan transit system, sodiceram tiles were used for flooring and wall cladding, delivering both durability and visual appeal. In another instance, aerospace companies selected sodiceram components for their engines, citing its performance under extreme conditions. These real-world successes highlight sodiceram’s potential in diverse fields.

Maintenance and Care Tips for Sodiceram Products

Caring for it is refreshingly simple. Regular cleaning with mild soap and water keeps surfaces looking new. For tougher stains, non-abrasive cleaners are recommended. It’s important to avoid dropping or striking sodiceram items, as sharp impacts can cause chips or cracks. Following these straightforward guidelines ensures longevity and continued performance.

Common Myths and Misconceptions About Sodiceram

Despite its popularity, several myths persist about it . Some believe it’s too delicate for industrial use, while others assume it’s prohibitively expensive. In truth, sodiceram’s engineered strength makes it suitable for heavy-duty roles, and its lifecycle costs are often lower than perceived. Dispelling these misconceptions helps more people appreciate the real benefits of sodiceram.

How to Select Quality Sodiceram

Choosing top-quality it means considering factors such as purity, density, and manufacturer reputation. Look for products that meet established industry standards and certifications. Reputable brands often provide detailed technical data, helping buyers make informed decisions. Consulting with material specialists or suppliers can also ensure you get the right sodiceram for your needs.

Comparing Sodiceram to Other Ceramic Materials

How does sodiceram stack up against porcelain, alumina, or other ceramics? Each material has its niche, but sodiceram’s blend of strength, thermal resistance, and electrical insulation sets it apart for many uses. While porcelain is prized for its beauty, and alumina for its hardness,it offers a unique balance of desirable traits, making it a versatile contender in the ceramics market.

Innovations in Sodiceram Manufacturing

Recent years have witnessed exciting advances in sodiceram manufacturing. 3D printing allows for complex, customized shapes, while nanotechnology is enhancing its mechanical properties. These innovations are reducing costs, improving quality, and enabling entirely new applications that were once out of reach.

Global Market Trends and Demand for Sodiceram

The demand for sodiceram is on the rise globally, driven by growth in construction, electronics, and advanced manufacturing. Emerging markets are adopting it for infrastructure and technological projects, while established industries continue to innovate with this trusted material. Market analysts predict a steady increase in it use over the next decade.

Environmental Impact and Recycling

Sustainability is at the forefront of modern manufacturing, and it leads the way with its minimal environmental footprint. Production methods are becoming more efficient, and recycling programs ensure that end-of-life sodiceram products are repurposed rather than discarded. Choosing it means supporting a cleaner, greener future.

Sodiceram

Sodiceram remains a symbol of modern engineering—combining the wisdom of traditional ceramics with cutting-edge advancements. Its properties make it a staple in countless applications, proving its worth time and again. Whether in construction, electronics, or healthcare, it is poised to remain a material of choice for years to come.

Frequently Asked Questions About Sodiceram

What is sodiceram made of?

It typically contains a blend of silicates, alumina, and special additives designed to enhance its strength, durability, and resistance to heat and chemicals.

How is sodiceram different from regular ceramic?

While regular ceramics are often used for decorative or light-duty applications it is engineered for high performance, offering superior mechanical and thermal properties.

Where is sodiceram most commonly used?

You’ll find it in construction (tiles, panels), electronics (insulators), aerospace (engine parts), and even in medical devices due to its unique characteristics.

Is sodiceram environmentally friendly?

Yes, sodiceram’s long lifespan, recyclability, and inert composition make it a sustainable choice for eco-conscious projects.

Can sodiceram withstand extreme temperatures?

Absolutely. It is renowned for its thermal resistance, maintaining structural integrity even under rapid and extreme temperature changes.

How do I care for sodiceram products?

Simple cleaning with mild soap and water is sufficient. Avoid dropping heavy objects on it to prevent chipping or cracking.

Conclusion: The Future of Sodiceram

Sodiceram is a testament to what can be achieved when science meets necessity. With its unparalleled properties and expanding range of applications, it is set to remain at the forefront of material science innovation. As industries evolve and demand more sustainable, reliable solutions, it’s role will only grow. Embracing it means choosing strength, sustainability, and future-ready technology.